- Joined

- Mar 1, 2000

- RO Number

- 6

- Messages

- 231

Use The Correct Thermostat

For engines to operate at maximum efficiency in terms of performance, fuel economy and emission levels it is important for the engine to get to the correct operating temperature as soon as possible and ensure that temperature is maintained during all operating conditions.

In order to do this manufacturers have redesigned their engines to utilise what is called a reverse poppet or bypass style thermostat. This style of thermostat has two valves instead of the one valve that is seen on a non-bypass thermostat. The primary valve operates exactly the same as the non-bypass thermostat and opens allowing coolant to flow to the radiator when the engine is at normal operating temperature. The secondary valve allows coolant to be circulated back through the engine during its warmup stage. The temperature of the engine is able to rise more evenly, minimising hot and cold spots in the engine. The primary valve begins to open and the secondary valve closes when the engine temperature rises. All coolant is then directed through the primary valve to the radiator ensuring that the correct operating temperature is maintained. A engine fitted with a bypass style thermostat must always have the correct bypass thermostat fitted. Engines fitted with non-bypass thermostats must always be fitted with the correct non-bypass thermostat. The fitting of an incorrect thermostat will cause the engine to run differently to how it was designed. Overheating and subsequent engine damage can be caused by using an incorrect thermostat.

Correct Bypass Thermostat In

The Correct Application

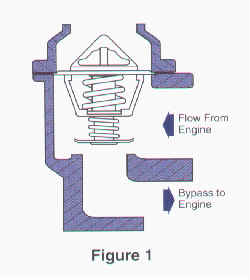

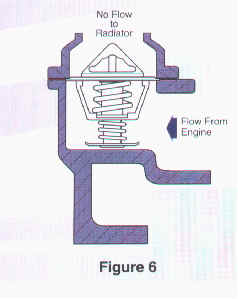

Figure (1) shows the installation of the correct bypass style thermostat. When the engine is cold the primary valve is closed preventing the flow of coolant to the radiator. The secondary valve is open and directs the flow of coolant back through the engine allowing it to warm up faster. As the engine warms up the primary valve begins to open and the secondary valve begins to close.

Figure (2) shows the secondary valve completely closed when the engine is up to proper operating temperature. The primary valve is then also completely open allowing full flow of coolant from the engine to the radiator.

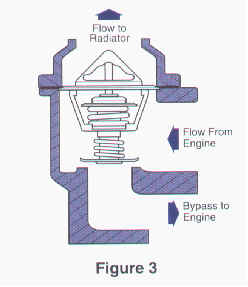

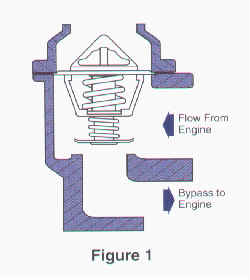

Incorrect Bypass Thermostat In A Bypass Application Figure (3) shows the use of an incorrect bypass thermostat in a bypass application. If the secondary valve is incorrect it may not close completely and coolant continues to flow through the bypass port even though the primary valve is fully open. This will cause hot coolant to return to the engine before it has been cooled. The engine temperature will be hotter than required and may cause premature failure of other components in the cooling system.

Non-Bypass Thermostat In A Bypass Application

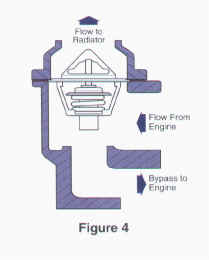

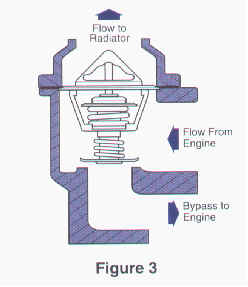

In this situation there is no secondary valve that will block off the bypass port when the engine warms up (Figure 4). This will cause hot coolant to continue to circulate through the engine without going to the radiator. The engine will run hotter than required and may cause a failure of other components in the cooling system.

Correct Non-Bypass Thermostat In The Correct Application

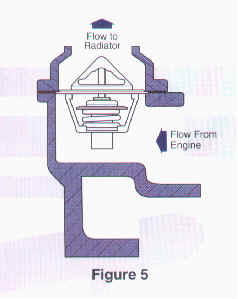

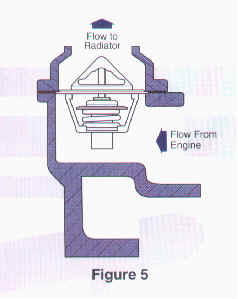

In engines with no bypass port a non-bypass thermostat must be used (Figure 5). No coolant flows until the thermostat opens. An incorrect non-bypass thermostat used in these applications will normally not physically fit or will be loose in the housing. Correct opening temperatures must also be used.

Bypass Thermostat In A Non-Bypass Thermostat Application

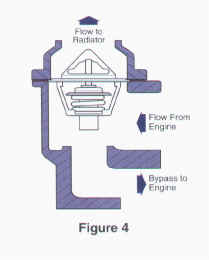

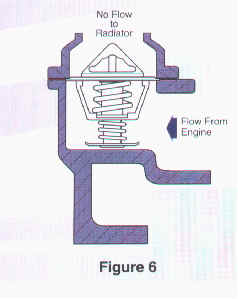

This is the worst possible combination as the secondary valve of the thermostat will hit the bottom of the housing (Figure 6) and prevent the thermostat from opening, as no coolant whatsoever will circulate and the engine will overheat and boil. Major engine damage may be caused as a result of this situation.

Thermostat Testing Procedures

Correct Field Procedure

The thermostat may be tested in any commercial type of tester for checking the thermostat operation. For accurate and valid results, the tests should be pedormed under carefully controlled conditions as follows:

1. Fill test container with 50% water 50% coolant concentrate.

2. Manually open the thermostat sufficiently to insert a fine thread under the valve seat.

3. Suspend thermostat by the thread in the container. The thermostat must be fully submerged and not touch the bottom or sides of the container.

4. Heat the liquid slowly to activate the power element properly. Agitation of the test fluid is required for accurate results.

5. Place a thermometer into the coolant so that the bulb is adjacent to the thermostat temperature sensing pill.

6. Observe the thermometer and note the temperature at once when the thermostat drops from the thread. This reading is the approximate start to open temperature of the thermostat.

7. The thermostat should be replaced if it opens at a temperature more than 10ГёF below or 5ГёF above the specified opening temperature. The temperature should be increased and the thermostat observed to make sure it fully opens. The thermostat should be fully open at a coolant temperature approximately 22ГёF above the specified opening temperature.

8. When cool carefully examine the thermostat valve to make certain it is properly seated. If it does not seat properly, it should be replaced. It is important the replacement thermostat be of similar design with the proper start to open temperature specifications.

For engines to operate at maximum efficiency in terms of performance, fuel economy and emission levels it is important for the engine to get to the correct operating temperature as soon as possible and ensure that temperature is maintained during all operating conditions.

In order to do this manufacturers have redesigned their engines to utilise what is called a reverse poppet or bypass style thermostat. This style of thermostat has two valves instead of the one valve that is seen on a non-bypass thermostat. The primary valve operates exactly the same as the non-bypass thermostat and opens allowing coolant to flow to the radiator when the engine is at normal operating temperature. The secondary valve allows coolant to be circulated back through the engine during its warmup stage. The temperature of the engine is able to rise more evenly, minimising hot and cold spots in the engine. The primary valve begins to open and the secondary valve closes when the engine temperature rises. All coolant is then directed through the primary valve to the radiator ensuring that the correct operating temperature is maintained. A engine fitted with a bypass style thermostat must always have the correct bypass thermostat fitted. Engines fitted with non-bypass thermostats must always be fitted with the correct non-bypass thermostat. The fitting of an incorrect thermostat will cause the engine to run differently to how it was designed. Overheating and subsequent engine damage can be caused by using an incorrect thermostat.

Correct Bypass Thermostat In

The Correct Application

Figure (1) shows the installation of the correct bypass style thermostat. When the engine is cold the primary valve is closed preventing the flow of coolant to the radiator. The secondary valve is open and directs the flow of coolant back through the engine allowing it to warm up faster. As the engine warms up the primary valve begins to open and the secondary valve begins to close.

Figure (2) shows the secondary valve completely closed when the engine is up to proper operating temperature. The primary valve is then also completely open allowing full flow of coolant from the engine to the radiator.

Incorrect Bypass Thermostat In A Bypass Application Figure (3) shows the use of an incorrect bypass thermostat in a bypass application. If the secondary valve is incorrect it may not close completely and coolant continues to flow through the bypass port even though the primary valve is fully open. This will cause hot coolant to return to the engine before it has been cooled. The engine temperature will be hotter than required and may cause premature failure of other components in the cooling system.

Non-Bypass Thermostat In A Bypass Application

In this situation there is no secondary valve that will block off the bypass port when the engine warms up (Figure 4). This will cause hot coolant to continue to circulate through the engine without going to the radiator. The engine will run hotter than required and may cause a failure of other components in the cooling system.

Correct Non-Bypass Thermostat In The Correct Application

In engines with no bypass port a non-bypass thermostat must be used (Figure 5). No coolant flows until the thermostat opens. An incorrect non-bypass thermostat used in these applications will normally not physically fit or will be loose in the housing. Correct opening temperatures must also be used.

Bypass Thermostat In A Non-Bypass Thermostat Application

This is the worst possible combination as the secondary valve of the thermostat will hit the bottom of the housing (Figure 6) and prevent the thermostat from opening, as no coolant whatsoever will circulate and the engine will overheat and boil. Major engine damage may be caused as a result of this situation.

Thermostat Testing Procedures

Correct Field Procedure

The thermostat may be tested in any commercial type of tester for checking the thermostat operation. For accurate and valid results, the tests should be pedormed under carefully controlled conditions as follows:

1. Fill test container with 50% water 50% coolant concentrate.

2. Manually open the thermostat sufficiently to insert a fine thread under the valve seat.

3. Suspend thermostat by the thread in the container. The thermostat must be fully submerged and not touch the bottom or sides of the container.

4. Heat the liquid slowly to activate the power element properly. Agitation of the test fluid is required for accurate results.

5. Place a thermometer into the coolant so that the bulb is adjacent to the thermostat temperature sensing pill.

6. Observe the thermometer and note the temperature at once when the thermostat drops from the thread. This reading is the approximate start to open temperature of the thermostat.

7. The thermostat should be replaced if it opens at a temperature more than 10ГёF below or 5ГёF above the specified opening temperature. The temperature should be increased and the thermostat observed to make sure it fully opens. The thermostat should be fully open at a coolant temperature approximately 22ГёF above the specified opening temperature.

8. When cool carefully examine the thermostat valve to make certain it is properly seated. If it does not seat properly, it should be replaced. It is important the replacement thermostat be of similar design with the proper start to open temperature specifications.